What is certification?

The product certification mechanism originated in the United Kingdom for 24 years. With the changes of the times, it has become an internationally accepted effective method for the evaluation, supervision, and management of product safety, quality, environmental protection, and other characteristics.

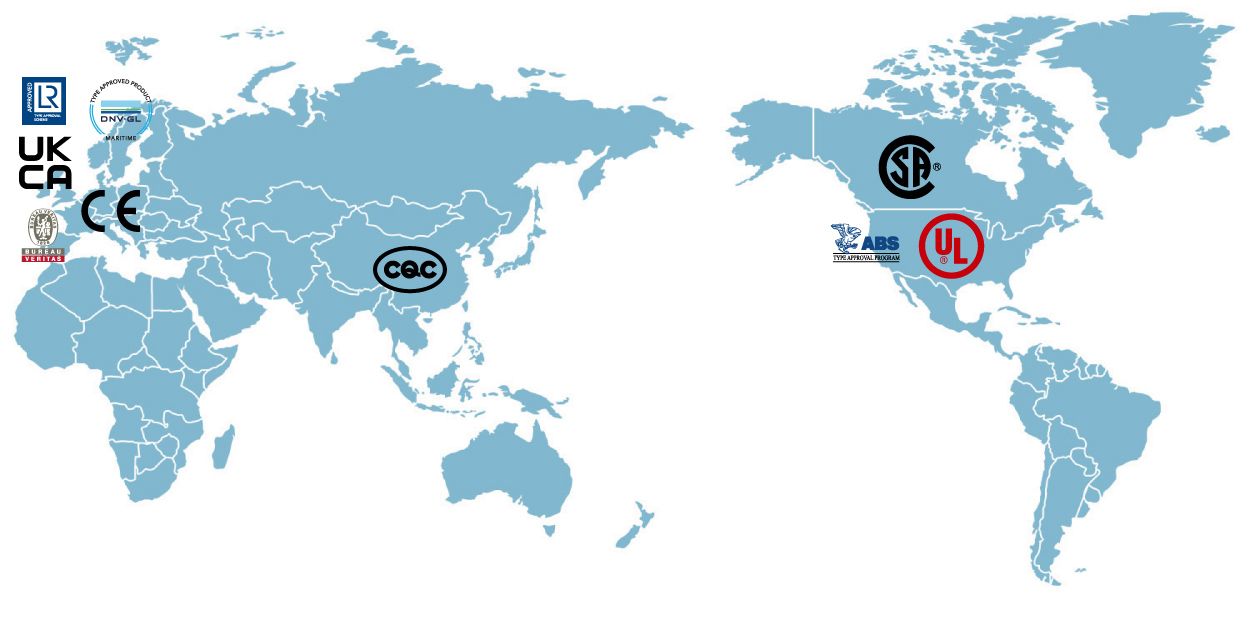

Most countries and regions in the world have set up their own product certification agencies, using different certification marks to indicate product certifications to relevant standards, such as UL Underwriters Laboratories safety testing and certification, CE EU safety certification, VDE German Electric Engineers Association certification, China CCC compulsory product certification and CCTP mark, etc.

The International Organization for Standardization (ISO) stated that the product certification requirement is to verify whether the company’s products, processes, or services meet specific requirements through the inspection of the quality management system and sample type tests of companies and whether they have the ability to continuously and stably produce the products required by the standards and the procedure of written certification.

Why we need certification?

The trend of globalization and the ever-changing buying behavior, the increasingly fierce competition. In this era, consumers want to purchase reassuring goods. In addition to considering a certain price/performance ratio, consumer expectations are increasingly tied to product safety, quality, and environmental requirements. Therefore, we believe that obtaining a certification mark for a company is the key to the market.

If a company's product has passed the product certification of a well-known national certification body, it can obtain a "certification certificate" issued by a national certification body and allow certification marks to be affixed to the certified products. This internationally recognized and effective certification method can enable companies or organizations to establish a good reputation and brand image through product certification, and at the same time allow customers and consumers to identify the quality and safety of products through certification marks. At present, governments all over the world have established this product certification system through legislation to ensure the quality and safety of products and safeguard the interests of consumers. This has become a new international trade barrier.

Certification conditions

The main content of product certification assessment is impartiality, legality, ability (product certification requires professional ability), and quality system. Generally required conditions are: quality system (environmental system) inspection and evaluation, type inspection, supervisory inspection, and supervision regular review. The first two elements are the necessary basic conditions for obtaining product certification qualifications, and the latter two elements are the supervision measures after product certification.

1.Type inspection approval

Type inspection for the purpose of certification is a process by which the certification authority conducts a series of tests and reasonable evaluations on one or more representative product samples to prove whether the tested samples meet their corresponding standards. It is the first important part of product safety certification. The basis of the type inspection is the relevant national standards of the product. The number of samples required for testing is determined by the certification authority in accordance with the requirements of laboratory testing. The sampling is randomly selected from the final product of the manufacturer. The type of inspection must be carried out by an independent inspection agency of the state or a third party. If there are individual special inspection items and the inspection agency lacks the required inspection equipment, it can use the manufacturer’s inspection equipment for inspection under the supervision of a third-party inspection agency or certification authority.

2.Quality system (environmental system) inspection and assessment

If an enterprise wants to ensure product quality and continuously meet the requirements of the standard, it must establish a quality management system according to the specific situation of the enterprise. Relying on sampling inspection of the final product to carry out product certification is not complete. Sampling inspections based on statistics can only prove the quality of a batch of products, and cannot prove whether the products produced in the future continue to meet the requirements of the standard. It is a practical and feasible method to prove that the company has the ability to continuously and stably produce products that meet the requirements of the standard by inspecting and assessing the company's quality management system.

3.Supervision and inspection

In order to maintain the stability of product quality and safety and to keep the products of the manufacturer in continuous compliance with the standard requirements, when finishing the product certification, it is necessary to conduct regular supervision and inspection on the certified products. The way doing supervision inspection is to take samples from the final products of the manufacturer or from the market and inspect them by an accredited and independent inspection agency. If the inspection result continues to meet the requirements of the standard, the mark is allowed to continue to be used; if the inspection result does not meet the requirements of the standard, necessary measures shall be taken according to the specific circumstances to prevent the continued use of the certification mark on products that do not meet the standard. It is important to check those items related to manufacturing, especially the quality and safety issues that customers have reported often. The cycle of supervision and inspection is generally once a year.

4.Supervision regular review

Supervision and inspection are the regular reviews of the quality assurance capabilities of the production enterprise, so that the enterprise insists on implementing the established quality system, so as to ensure the stability of product quality. This is a monitoring measure for certification quality. The internal visitor of the supervision and inspection is simpler than the first system inspection. The point is to check whether the non-conformities in the previous inspection have been effectively corrected and whether the modification of the quality (environment) system meets the requirements of quality and environmental indicators.

.jpg?v=7ec45b5f)