Residential Junction Box

Residential Junction Box/ Interior Design Industry

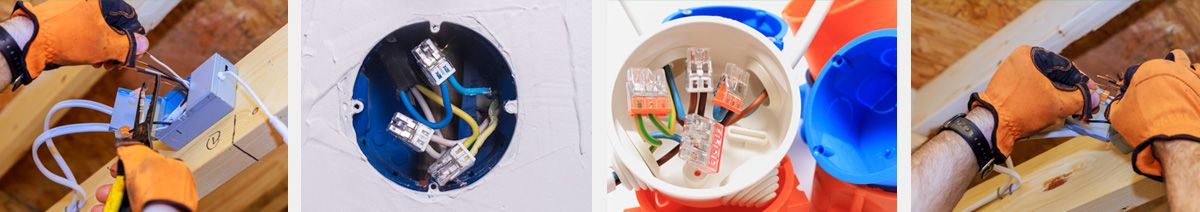

When inspecting your home's electrical system, you'll find various components, including cables, outlets, switches, circuit breakers, and an essential box known as the junction box. This junction box is designed to protect the electrical connections inside, preventing potential electric shock incidents and effectively containing sparks from spreading to nearby flammable materials. Junction boxes have become a standard feature in modern residential construction, with nearly every household installing multiple boxes to ensure the safety of wire connections and to mitigate the risks of electrical fires and other hazards. These junction boxes are commonly used in circuits for lighting, outlets, and various appliances.

According to the National Electrical Code (NEC) and local building regulations, the installation of junction boxes is mandatory to ensure the safety and compliance of the electrical system. As a result, junction boxes provide a code-approved enclosure for housing wire connections, whether for outlets, switches, or splices, ensuring they are properly secured and protected.

There are two types of junction boxes: new work boxes, which are typically installed when the wall framing is open, and old work boxes, which are installed after the drywall is in place.

In residential construction, there are numerous choices, whether you're building a custom single-family home or developing an entire subdivision. Each choice affects the cost and quality of the home, and electrical enclosures play a significant role in this process. Choosing the right type of junction box can reduce costs and provide better options for wiring the entire house. Common materials for junction boxes include polycarbonate (PC), fiberglass, and metal.

1.Polycarbonate (PC)Polycarbonate is the most common material used for indoor electrical boxes. It is highly affordable, with each box costing less than those made from other materials. Importantly, it provides everything needed for indoor use. Polycarbonate is an excellent electrical insulator and is easy to modify if you need to customize the box. Additionally, it has an aesthetic appeal, leaving no unsightly surface exposure in applications where the box might be visible. The greatest advantage of polycarbonate is that it is suitable for all common residential applications, including junction boxes, outlets, switches, and fan boxes.

2.Fiberglass

Fiberglass is another excellent insulator that is easy to modify and sufficiently durable for indoor use. It is also affordable. However, polycarbonate is increasingly being used in residential applications for two main reasons. While fiberglass is highly resistant to strong solvents and other harsh chemicals, this characteristic is less critical in residential applications. Moreover, the cost of fiberglass is usually higher than that of polycarbonate, leading most developers and interior designers to opt for the more economical choice.

3.Metal

The use of metal enclosures in residential settings is relatively uncommon, primarily reserved for wiring with metal-sheathed conduit. In such cases, metal provides the additional grounding needed. However, this is not a frequent requirement in new construction, and most often, you will find metal boxes used for outdoor applications. Metal is an excellent weatherproof option, especially for outdoor circuit breakers. In most cases, outdoor junction boxes are made from aluminum, though galvanized steel can sometimes be seen. Aluminum junction boxes are generally the better choice due to their superior weather resistance and rust prevention capabilities.

Junction Box Dimensions

The size of a junction box is determined by the number of wires it needs to accommodate. Overcrowding a junction box can significantly increase the risk of fire. According to the National Electrical Code (NEC), the correct size of a junction box should be based on the number and size of the wires it contains. Wire size is measured using the American Wire Gauge (AWG) system, where a lower number indicates a thicker wire. Common household wiring typically uses 16, 14, or 12 AWG wires, which correspond to 1.5, 2.5, or 4.0 mm² in European standards. Each conductor requires a certain amount of space, as specified by regulations. According to NEC Section 314.16(B), each 14 AWG wire requires 2 in³ (approximately 32.77 cm³) of space. In contrast, the European IEC 60670-1 standard generally requires at least 20 cm³ of space for the installation of a 2.5 mm² wire. The specific space requirements may vary depending on local building codes or special installation environments. To make installation easier, many DIY enthusiasts may opt for a larger box that better suits their application needs.

Tools and Materials You May Need for Installing a Junction Box

Before beginning the installation, it's advisable to review your local electrical codes to ensure that all materials and tools comply with safety standards.

| Illustration Photo | Materials Needed | Applications |

| Junction Box | Protects wire connections from potential hazards |

| Screws | Secures the junction box and panel |

| Wire Connectors | Connects wires together (Contact Hua Wei Industrial for Products) |

| Cable Ties | Used for organizing and securing wire bundles, ensuring wires are neatly arranged within the junction box (Contact Hua Wei Industrial for Products) |

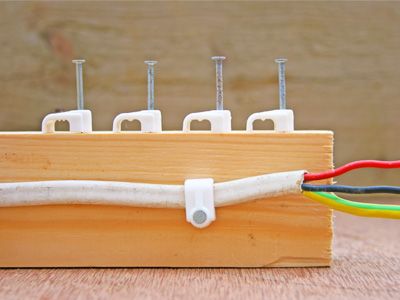

| Steel Nail Clips | Especially useful in wood-framed installations, steel nails can be used to secure the junction box in place, preventing wires from shifting and causing poor connections. (Contact Hua Wei Industrial for Products) |

| Screwdriver | Tightens screws |

| Wire Stripper | Strips insulation from wires to expose bare wire for connection |

| Voltage Tester | Ensures the circuit is de-energized and performs testing |

| Electric Drill | Used for drilling holes and securing components |

Hua Wei Industrial: Reliable, Certified Products Tailored to Your Needs

Hua Wei Industrial offers reliable products that meet safety certifications, with a wide range of specifications to ensure compatibility. Our solutions are tailored to meet your specific needs while also being cost-effective, saving you both money and valuable time.

- Nylon Cable Ties: Hua Wei Industrial’s nylon cable ties are designed for bundling and securing wires, cables, hoses, and more. Available in heat-resistant, weather-resistant, and flame-retardant materials, our standard nylon cable ties come in a variety of tensile strengths ranging from 18 to 250 lbs, with a selection of lengths and colors. They are certified by UL, CE, ABS, REACH, RoHS, and HF.

- Steel Nail Clips: Hua Wei Industrial’s steel nail clips feature high elasticity, capable of withstanding impact without cracking. Simply insert the steel nail, fasten the plastic base, and you're done—saving time and reducing costs. These clips are certified by CSA, RoHS, and HF.

- Push-In Connectors: Hua Wei Industrial’s push-in connectors provide an intuitive termination solution for 22-12 AWG solid wires. The color-coded design makes it easy to identify connection points, while the compact size ensures a seamless fit in tight spaces. Ideal for lighting installations, pre-fabricated wiring systems, and circuit wiring, these connectors eliminate the need for complicated twisting. Simply push the wire in for a quick and reliable connection. With their compact and transparent design, Hua Wei's push-in connectors have become an essential choice for electrical installations, offering a new level of convenience for your wiring tasks. They are certified by UL, IEC, VDE, UKCA, REACH, and RoHS.

Have you gathered all the necessary materials and tools? Continue reading our Wiring and Installation Guide for Junction Boxes, or Contact Us directly for more expert advice.

Why Choose Hua Wei?

- Over 45 years experiences in designing and manufacturing of cable ties.

- Core technology: Precise stamping and molding injection.

- Rich experience and specialty of precise molding in engineering plastic Polyamide 6,6

- Advanced molding facilities and outstanding R&D teamwork

- Our in-house molding capability allows great flexibility in production and enables us to develop products collaboration with our clients.

- Providing customize packaging design and work in process with your brand.

- Stable supply chain with on-time delivery.

Remarks: Hua Wei is a professional OEM factory, followed the MOQ for each order.

Featured product

Hot

Hot

Stainless Steel Ties

Hot

Hot

Stainless Steel Ties

With high resistance to various corrosive agents such as acids, alkali, UV, and rust, …

Read More Hot

Hot

Wire Ducts

Hot

Hot

Wire Ducts

The premium solution for routing and hiding wires in control panels.

Read More Hot

Hot

Standard Cable Ties

Hot

Hot

Standard Cable Ties

Available materials include heat stabilized, weather resistant and flame retardant polymers,...

Read More Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

The new cable tie installation tool can fasten and cut nylon cable ties quickly & safely

Read More

.jpg?v=7ec45b5f)