Automotive

Hua Wei’s Experienced Developing Capability for Automotive Fasteners

With over 45 year experience on precise stamping and precise molding injection, Hua Wei has provided industrial standard cable ties and fasteners, and customized variable automotive and engineering fasteners to fulfill the unique requirement of secure and sustainable. Automotive fasteners of Hua Wei apply to high vibration and harsh environment and can fasten wires securely. Applicable vehicles are included sedans, trunks, wagons, trailers, excavators, etc.

With ISO 9001 and IATF 16949 accreditations, Hua Wei guarantees to provide best service and optimized quality throughout the management system. QA system and regular examination assure the products are qualified before delivery.

Technologies of precise stamping and molding injection, excellent RD teamwork, and premium quality make Hua Wei the first choices as an automotive OEM service provider and partner.

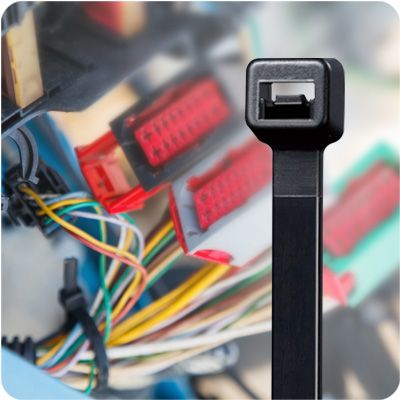

Cable ties are commonly used in the automotive industry for bundling and securing wires, cables, and hoses. Wiring components play a crucial role in automotive design and manufacturing. Cable ties, as well as stainless steel ties, are used to secure and bundle wires and cables together, while fixing mounts help maintain wiring stability and neatness. Proper selection and use of these tools ensure vehicle safety and reliability.

In the automotive industry, cable ties come in various materials and design forms. When choosing cable ties for automotive use, the following points need to be considered:

1. Materials:

Automotive cable ties are typically made of nylon, stainless steel, or hook and loop fasteners. Nylon is the most widely used material. In automotive cable ties, nylon is often blended with other materials to enhance resistance to heat, UV, and chemicals. Stainless steel cable ties, on the other hand, can withstand higher temperatures and are more resistant to radiation, vibration, and flames.

2. Design forms:

Different designs of cable ties bring various benefits to the automotive industry, including improved efficiency, space management, enhanced shock resistance, and time and cost savings. These design improvements contribute to the quality and reliability of automotive products while improving the production process and user experience.

3. Size and tensile strength:

Automotive cable ties range in length from 100mm to over 400mm. However, the length or width of a cable tie does not necessarily indicate its strength. Cable ties are graded based on their tensile strength. LTS corresponds to the maximum force that can be applied after the cable tie is locked. The standard range of tensile strength for automotive cable ties is from 8kgf to 114kgf.

4. Bundle diameter:

When selecting the specifications of cable ties, "maximum diameter" refers to the maximum diameter of the bundle or harness you want to secure. Ensure that the chosen cable tie is long enough to wrap around your bundle and leave enough slack on the tie for threading and locking.

Hua Wei's products provide perfect wire management solutions for the automotive industry.

AUTOMOTIVE APPLICATION

DIVERSE MATERIAL CABLE TIES

SPECIAL DESIGN CABLE TIES

|

|

|

|

Double Loop Cable Ties |

Push Mount Cable Ties |

Lashing Ties |

|

|

|

|

Quick Releasable Cable Ties |

Push-In Mounts |

Chassis Cable Ties |

CABLE TIE ACCESSORIES

|

|

|

|

Self Adhesive Wire Saddles |

Self Adhesive Wire Clamps |

PA12 Upgraded UV Resistance Adhesive Tie Mounts |

| ||

|

P Clamps |

CABLE PROTECTION

|

|

|

|

Spiral Wrapping Bands |

Flexible Conduits |

Tarpaulin |

|

|

|

|

Cable Glands |

American Type Hose Clamps |

German Type Hose Clamps |

CABLE TIE TOOLS

|

| |

|

Tools for Plastic Cable Ties |

Tools for Stainless Steel Cable Ties |

Introduction to commonly used tools in the automotive industry:

- General Cable Ties (Nylon 6,6 cable ties): These cable ties are made of nylon 6,6 material, providing excellent strength and wear resistance. They are widely used for wire fixing and management in automotive applications and often feature a self-locking mechanism for easy and secure fastening.

- Tefzel/ETFE Cable Ties: Tefzel/ETFE cable ties have chemical resistance, making them suitable for environments with exposure to various chemicals. They are used for securing wires, connectors, and sensors in vehicles, ensuring proper functioning and safety of the electrical system.

- Heat-Stabilized Cable Ties: Heat-stabilized cable ties are designed specifically for high-temperature environments. They utilize special materials or additives to enhance heat resistance, withstand deformation, and prevent degradation in high-temperature conditions.

- Extra/ Heavy Duty Cable Ties: Heavy-duty cable ties with a tensile strength ranging from 54kgf to 114kgf are used for securing automotive parts that may endure harsh environments and severe vibrations, such as shock absorbers, batteries, and cables. They minimize compression and damage to soft bundles.

- PA12 Extremely UV Resistant Cable Ties: If your cable ties will be exposed to sunlight, it is important to ensure they have UV resistance.

- Flame Resistant Cable Ties: Cable ties with UL94 flame resistance ratings are highly reliable, as they do not melt even when exposed to open flames.

- Stainless Steel Cable Ties: Stainless steel cable ties offer high strength, durability, and corrosion resistance. They find applications in automotive body structures, engines, vehicle maintenance and repair, theft prevention and security, as well as charging equipment at electric stations.

- Double Loop Cable Ties: Double loop cable ties have two fixing holes, allowing them to secure multiple wires or pipes. They are suitable for scenarios that require bundling multiple cables, providing parallel separation and improved installation flexibility.

- Push Mount Cable Ties: These cable ties feature a push mount design for convenient fastening to vehicle structures or holes. They can be quickly installed and provide a secure fixing effect. They can also be mounted to another surface for added stability.

- Arrow Head Cable Ties: Arrow head cable ties have a special arrow-shaped design that allows for easy insertion through holes and secure fastening in the desired position. This design provides a more secure fixing effect and can be mounted to another surface for added stability.

- Lashing Ties: A unique flat buckle design that offers a more secure fastening effect. They are often used in scenarios that require resistance to strong vibrations and external forces to ensure wiring stability.

- Quick Release Cable Ties: These cable ties feature a quick release mechanism, allowing for fast and easy loosening and repeated opening and closing. They are convenient for maintenance and replacement scenarios that require frequent adjustments.

- Chassis/ Bottom Head Cable Ties: Chassis/Bottom Head Cable Ties are widely used for securing cables and wire harnesses in the chassis of vehicles, including automobiles, trucks, and heavy equipment. They utilize a single hole for fastening, ensuring that the wire bundles are securely fixed to the frame rails, thus providing a safe and stable connection that prevents shaking and damage.

- Cable Clamps: Typically made of plastic, cable clamps have the function of securing pipes or wire bundles. They provide flexible installation options by allowing wire fixing at different angles.

- Push-In Mounts: The design of push-in mounts enables convenient and efficient installation by simply inserting them into pre-drilled holes, providing a quick and reliable way to secure components. These mounts find wide applications in the automotive industry, including wire harness mounting, pipe fixing, dashboard attachment, seat installation, etc.

- Cable Tie Tools: These tools allow for pre-setting the desired tension and then squeezing the handle until the cable tie is precisely tightened and cut, avoiding any residual tail on the tie.

Contact us for more industry expert advice.

Download the product brochure.

Why Choose Hua Wei?

- Over 45 years experiences in designing and manufacturing of cable ties.

- Core technology: Precise stamping and molding injection.

- Rich experience and specialty of precise molding in engineering plastic Polyamide 6,6

- Advanced molding facilities and outstanding R&D teamwork

- Our in-house molding capability allows great flexibility in production and enables us to develop products collaboration with our clients.

- Providing customize packaging design and work in process with your brand.

- Stable supply chain with on-time delivery.

Remarks: Hua Wei is a professional OEM factory, followed the MOQ for each order.

Featured product

Hot

Hot

Stainless Steel Ties

Hot

Hot

Stainless Steel Ties

With high resistance to various corrosive agents such as acids, alkali, UV, and rust, …

Read More Hot

Hot

Wire Ducts

Hot

Hot

Wire Ducts

The premium solution for routing and hiding wires in control panels.

Read More Hot

Hot

Standard Cable Ties

Hot

Hot

Standard Cable Ties

Available materials include heat stabilized, weather resistant and flame retardant polymers,...

Read More Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

The new cable tie installation tool can fasten and cut nylon cable ties quickly & safely

Read More

_Cable_Ties-4R.jpg)

.jpg?v=7ec45b5f)