How to Verify the Weather Resistance of Plastics?

Xenon Arc Accelerated Weathering Test Methods for Solar Cable Ties

To verify the weather resistance of plastics, methods such as natural exposure and artificial accelerated tests are mainly adopted. However, since natural exposure is direct exposure in the natural environment, this method is extremely time-consuming, and is affected by environmental factors, and has low reproducibility. Therefore, the weather resistance of materials is mainly based on artificial aging tests, and the most common method is light aging test.

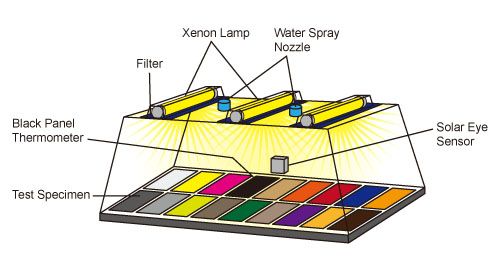

1. Xenon Arc Accelerated Weathering Test Methods

Xenon Arc weatherometers simulate the weathering process of indoor and outdoor sun exposure on materials. The spectral range of the xenon arc lamp is ultraviolet light, visible light and infrared radiation with a wavelength greater than 270nm. After proper filtering, its energy distribution is most similar to the visible light part of the sunlight. Usually, the test temperature is 65°C±3°C, humidity is 50±5% or 65±5%, water spray time/non-water spray time period is 18±0.5 min/102±0.5 min, irradiation energy is 550 W/m2, others It can refer to the international standard ISO 4892-2, and Hua Wei's solar energy strap testing is also based on the international standard ISO 4892-2 standard method. The xenon arc lamp has high analogy, but the low- accelerated speed is its shortcomings.

2. Carbon Arc Test

Carbon Arc testing uses a weathering system that emits ultraviolet, visible and infrared radiation when an electric current is passed between its carbon rods. Carbon Arc testing measures a product’s ability to resist deterioration of electrical, mechanical and optical properties when exposed to light and heat.

3. Ultraviolet (UV) Exposure Test

UV Exposure testing uses fluorescent UV lamp weathering devices to simulate exposure to natural sunlight. This test measures the effect of ultraviolet light on the mechanical properties of a product.

4. Other Weathering Test Methods

Such as fog, salt spray & Corrosion Testing.- In a typical salt spray test, a standardized solution of 5% NaCl (sodium chloride) is used to create a highly corrosive atmosphere.

- Sand & Dust Testing: How components, vehicles and systems perform when exposed to desert sand and dust can be vitally important, not just to the operator during use, but to the product’s lifetime overall performance. This test requires sand blowing and dust, and the test temperature, humidity, wind speed and particle concentration values are recorded.

The Weathering Test method of Hua Wei’s Solar Cable Ties

Hua Wei uses xenon arc aging test equipment according to the international ISO 4892-2 test standard, and sets the rainwater cycle to 18mins/102mins according to the standard, and the illuminance range is 638 W/m2. All the cable tie specifications listed by Hua Wei have been tested by UV 3600 hours.

According to the experimental standard, 150 hours of xenon arc aging test is equivalent to 1 year of exposure, and 3600 hours is 24 years. It can be calculated that the total annual exposure of the environment simulated by this standard is 6,890 MJ/m2. And such an annual amount of sunshine and environment, whether in tropical climate, subtropical climate, temperate climate, cold zone climate, or even desert climate, are trustworthy; and it can respond to the life of the photovoltaic system of the solar field.

On the other hand, it is worth noting that the relevant data of the test method is the experimental measurement value in accordance with the international standard aging method. The actual environmental situation cannot be guaranteed, because these test methods are reference data obtained under certain conditions and cannot represent the actual lifetime.

Hua Wei Industrial Co., Ltd. is your best supplier!

Base plastics not designed for harsh environments can erode fast. Therefore, it is recommended to use Soar Cable Ties and related series products specially designed for the extreme weather event and photovoltaics / solar energy industry.

To know more about zip ties, cable mounts, clamps and series products for photovoltaics / solar energy, please contact us.Featured product

Hot

Hot

Stainless Steel Ties

Hot

Hot

Stainless Steel Ties

With high resistance to various corrosive agents such as acids, alkali, UV, and rust, …

Read More Hot

Hot

Wire Ducts

Hot

Hot

Wire Ducts

The premium solution for routing and hiding wires in control panels.

Read More Hot

Hot

Standard Cable Ties

Hot

Hot

Standard Cable Ties

Available materials include heat stabilized, weather resistant and flame retardant polymers,...

Read More Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

The new cable tie installation tool can fasten and cut nylon cable ties quickly & safely

Read More

.jpg?v=7ec45b5f)