Introduction the characteristics and application of Nylon 12 (Polyamide 12 / PA 12) material

Nylon 12 Material Introduction and Characteristics

Nylon 12 is a nylon polymer. It is made from ω-amino lauric acid or laurolactam monomers that each have 12 carbons, hence the name “Nylon 12”. Its characteristics are between short-chain aliphatic nylons (such as PA 6 and PA 66) and polyolefins. PA 12 is a long carbon chain nylon. Low water absorption and density, 1.01 g/mL, result from its relatively long hydrocarbon chain length, which also confers it dimensional stability and an almost paraffin-like structure. The Nylon 12 properties include the lowest water absorption characteristics of all polyamides, which means any parts made from PA 12 should remain stable in humid environments.

In addition, polyamide 12 with good chemical resistance, with reduced sensitivity to stress cracking. Under relatively dry operating conditions, the sliding friction coefficient of steel, POM, PBT and other materials is low, with excellent wear resistance, stability, very high toughness, and impact resistance. Meanwhile, PA 12 is a good electrical insulator and, like other polyamides, does not affect insulation by moisture. Besides, PA 12 long glass fiber reinforced thermoplastic material has good noise and vibration damping.

Significant suppliers of polyamide 12 include EMS-Chemie, the Marl Chemical Park operated by Evonik, Arkema and SH Energy & Chemical.

Application of Nylon 12 Materials

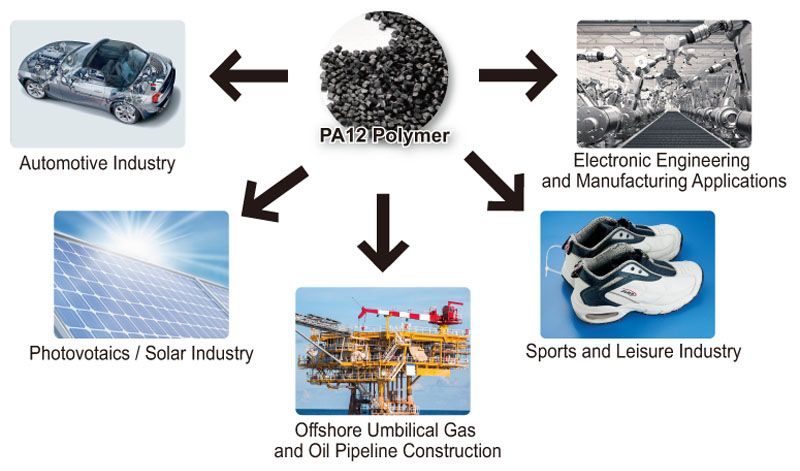

Typical application areas for PA12 are the fields of automotive, phtovoltaics(PV), offshore umbilical gas and oil pipeline construction, electric and electronic, and leisure and sport. The following describes the applications in various fields:

1. Automotive Industry

PA 12 has been used as a plastic in the automotive industry for many years: examples of multilayer pipes made of PA 12 include fuel lines, pneumatic brake lines,hydraulic lines, air intake system, air boost system, hydraulic system, automotive electronics and lighting, cooling and air conditioning system, oil system, power system and chassis in the vehicles of countless automobile manufacturers worldwide. Its chemical resistance and outstanding mechanical properties make PA 12 an ideal material for contact media that contain hydrocarbons.

2. Photovotaics / Solar Industry

On solar tracker systems, install wire management every 4 ft or less along the torque tube or secured to the module frame. Ensure cable has some slack to allow for thermal cycling.

It is worth noting that the cable management system should avoid sharp edges. Do not thread products through module mounting holes alone. Movement can lead to premature damage and product failure. By the way, you can also use the cable tie mounts series to secure it (click to see how to install the zip tie mounts), which can effectively avoid the shaking of the cable.

In addition, A failed cable tie can lead to a downed wire and potential inverter ground faults. Adding to regular wear and tear, extreme environments such as deserts, where temperatures can range from -20°F (-29°C) to 120°F (+49°C), can further stress materials.

Therefore, Two considerations are extremely important when evaluating zip tie options:- Materials and price

- The application of the system

3. Offshore Umbilical Gas and Oil Pipeline Construction

Some polyamide 12 grades were specifically developed for energy efficient gas and oil pipelines. These polyamides have extraordinary resistance to mechanical stress, stress fracturing, and chemicals such as crude oil. Thanks to these properties, they can be used to protect the exterior and interior of onshore and offshore oil and gas pipelines against corrosion and chemicals.

4. Sports and Leisure Industry

Polyamide 12 is used to manufacture bicycle derailleur, sport shoes (shoe soles), etc., thanks to its good grease and abrasion resistance and low coefficient of friction.

5. Electronic Engineering and Manufacturing Applications

In engineering/ manufacturing applications like protective layer of water pipes, air and spray-painting hoses, electrical appliances, connectors, mobile phones and other portable devices is widely used.

Differences between PA 12 and PA 66

In a weather event, basic nylon ties will dry out in the heat and re-absorb the moisture in the environment, picking up zinc chloride and other minerals, which enters the cable and destroys it from within. This is extremely important to understand because tracker and fixed-tilt systems are often made of galvanized steel, which corrodes over time, leaving a bunch of zinc chloride. In addition to causing internal damage to the cable, zinc chloride will also make the PA 66 zip ties become easier to break.

However, PA 12 has many improvised varieties in terms of plasticizing properties and reinforcing properties. Compared with PA6 and PA66, these materials have lower melting point and density and have very high moisture regain.

In addition, in the Xenon Arc Accelerated Weathering Test, in accordance with the ISO-4892-2 test standard, it can be found that the tensile performance of the general PA 66 cable tie has a sharp drop after the xenon arc aging test in the experimental environment for 200 hours; PA 66 UV is about 1,000 hours; however, PA 12 has a very good tensile performance in the UV environment test, and it can last for more than 3600 hours.

_Cable_Ties_Weathering_Test-2.jpg)

Differences between PA 12 and PA 11

Nylon PA11 is a bioplastic polyamide powder made out of renewable resources that come from vegetable/castor oil. In addition, it only has one manufacturer, which is Arkema. Since it is extracted from plants, the manufacturing process reduces the use of a large amount of non-renewable substances, which has a lower environmental impact, but is limited by its output.

Nylon PA12, on the other hand, is a subtle synthetic power cultivated from petroleum materials, and has several manufacturers, such as Arkema again and Evonik. As for PA12, though not as eco-friendly, it can withstand drastic temperature drops, even staying strong in below freezing periods. Overall, it is stiff, resistant to cracking, and demonstrated profound long-term quality.

Hua Wei Industrial Co., Ltd. is your best supplier!

Base plastics not designed for harsh environments can erode fast. Therefore, it is recommended to use PA 12 cable ties and related series products specially designed for the extreme weather event and photovoltaics / solar energy industry.

To know more about zip ties, cable mounts, clamps and series products for photovoltaics / solar energy, please contact us.Featured product

Hot

Hot

Stainless Steel Ties

Hot

Hot

Stainless Steel Ties

With high resistance to various corrosive agents such as acids, alkali, UV, and rust, …

Read More Hot

Hot

Wire Ducts

Hot

Hot

Wire Ducts

The premium solution for routing and hiding wires in control panels.

Read More Hot

Hot

Standard Cable Ties

Hot

Hot

Standard Cable Ties

Available materials include heat stabilized, weather resistant and flame retardant polymers,...

Read More Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

The new cable tie installation tool can fasten and cut nylon cable ties quickly & safely

Read More

.jpg?v=7ec45b5f)