Ball Lock Type Stainless Steel Ties

Stainless steel ties are designed to secure hoses, cables, poles, pipes, and more when harsh environmental conditions may adversely affect the bundling application and used where corrosion, vibration, weathering, radiation, and temperature extremes are a concern, stainless steel ties can be used in virtually any indoor, outdoor, and underground application.

OPERATING INSTRUCTIONS

| 1. Wrap the stainless steel cable tie on the object and tighten it up. |

| 2. Insert the stainless steel cable tie strap through the tension tool and place the cutting head against the head of the cable tie. |

| 3. Press the trigger until the cable tie strap is cut off |

| 4. Finish. |

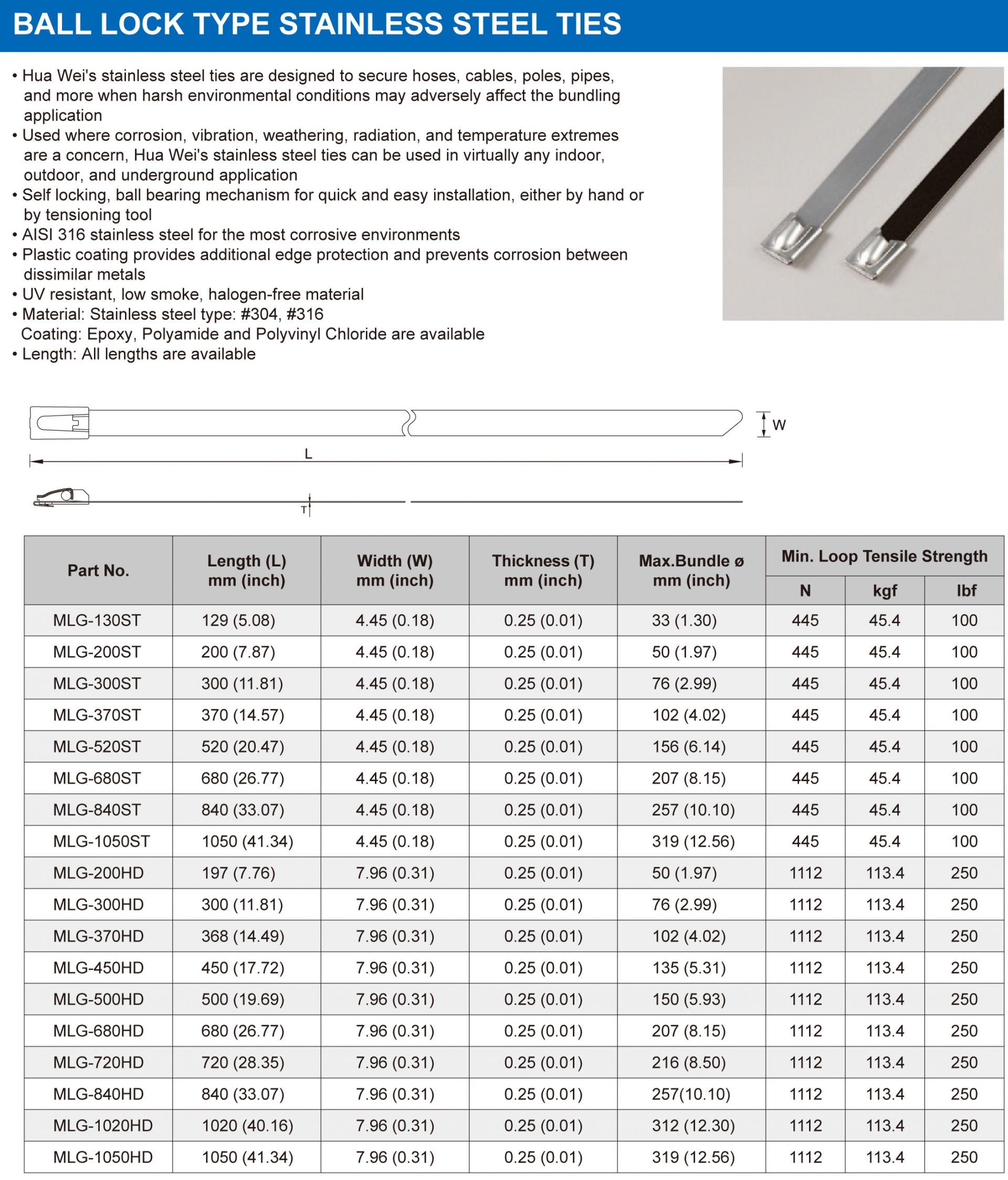

SPECIFICATIONS

TECHNICAL INFORMATION

Stainless steel is a steel alloy with increased corrosion resistance compared to carbon/alloy steel. Common applications include food handling/processing, medical instruments, hardware, appliances, and structural/architectural uses.

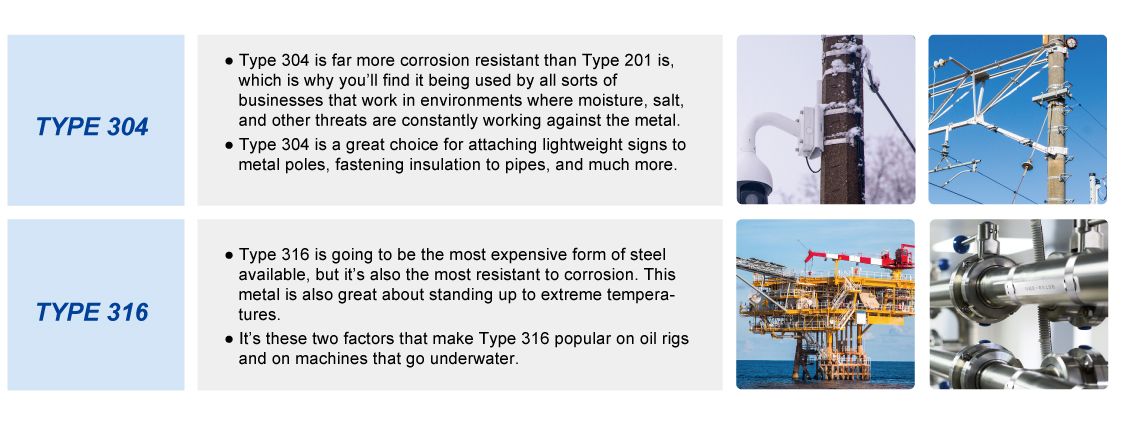

Different Alloys of Steel Banding and Buckle

There are many different grades of steel that encompass varied properties. These properties can be physical, chemical and environmental. When it comes to stainless steel banding and buckle, there are generally only two worth considering. These are:

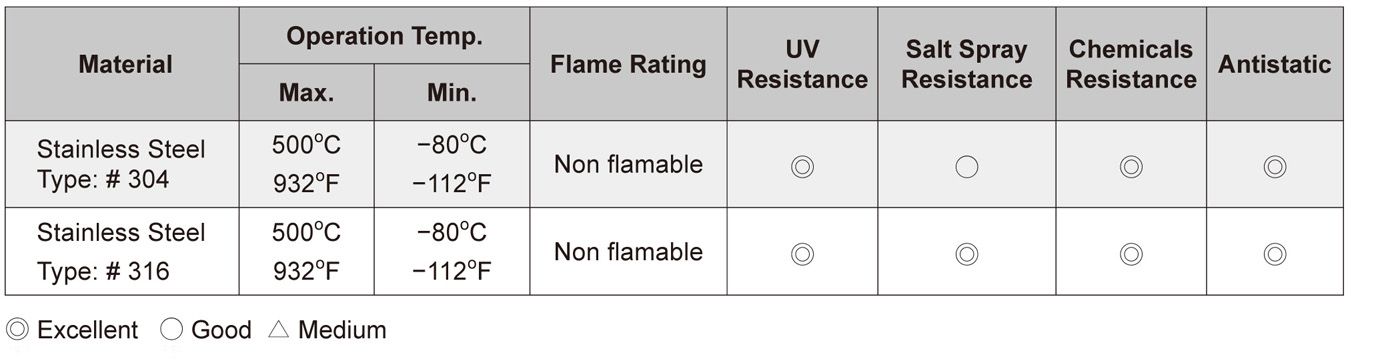

Stainless Steel Material Descriptions

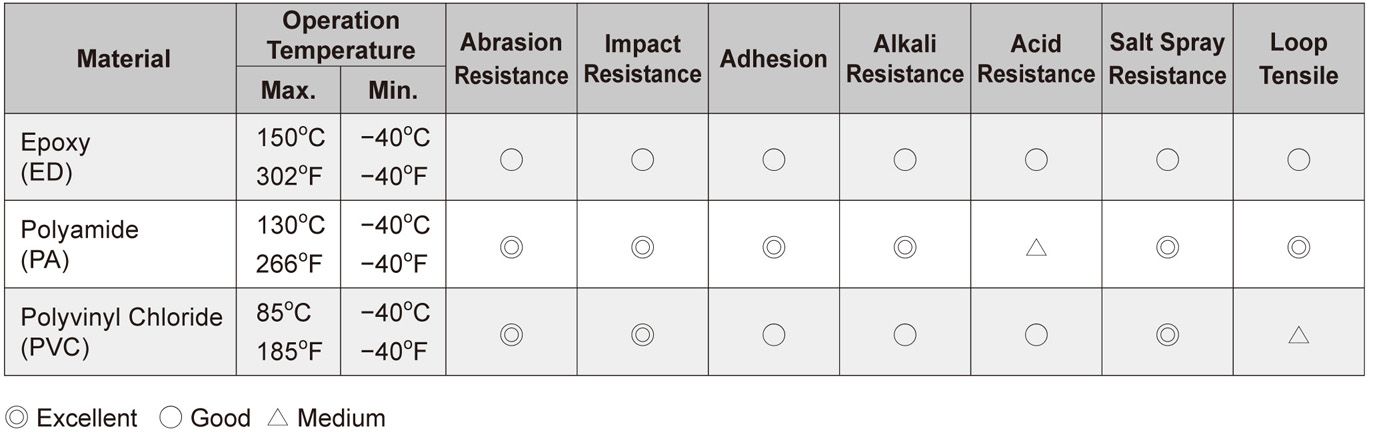

Coating Material Descriptions

RELATED PRODUCTS

| Stainless Steel Tie Tools speed installation and provide the lowest total installed cost. |

| Stainless Steel Marker Plates are used to permanent identification of pipes, conduit, valves, cables and equipment in harsh environments. |

| Stainless steel Strapping and Buckles can be cut any length to fit for hoses/pipe of all sizes. Convenient and durable for mounting traffic signs, commercial signs, holiday decorations, etc. |

| Releasable Type Stainless Steel Ties are releasable and can double-wrapped for additional tensile strength. Suitable for petrochemical and food processing industries, power stations, mining, shipbuilding, offshore and other aggressive environments. |

| Wing Seal Type Stainless Steel Ties are low profile tie head design, which are ideal for use in the restricted space. Double wrapping is allowed for special strength requirements and reliable installation. |

MAINTENANCE

These products will be free from defects in material and manufacture at the time of purchase. Shelf life on stainless steel strapping and buckles are 5 years from the date of production when stored in original packaging and humidity controlled storage (10°C/50°F to 27°C/80°F and <75% relative humidity).

CAUTION

For industrial or professional use only. Before using this product, you must evaluate it and determine if it is suitable for your intended application.

WARNING

- Please keep out of reach of children.

- Confirm that steel strap and buckle are in good condition before use.

- Once cutted, the strap of cutting edge may be sharp.

- Once tightened, steel strap may be difficult to loosen.

- Always wear approved eye protection and protective gloves.

- Not Insulated. Stainless steel strap and buckles are not insulated for protected against electrical shock.

- Catalogue

Ball Lock Type Satinless Steel Ties Flyer

Describe about features, materials, specifications of Ball Lock Type Satinless Steel Ties

Ball Lock Type Stainless Steel Ties Catalogue (Uncoated)

Describe about features, materials, specifications of Ball Lock Type Stainless Steel Ties

Featured product

Hot

Hot

Stainless Steel Ties

Hot

Hot

Stainless Steel Ties

With high resistance to various corrosive agents such as acids, alkali, UV, and rust, …

Read More Hot

Hot

Wire Ducts

Hot

Hot

Wire Ducts

The premium solution for routing and hiding wires in control panels.

Read More Hot

Hot

Standard Cable Ties

Hot

Hot

Standard Cable Ties

Available materials include heat stabilized, weather resistant and flame retardant polymers,...

Read More Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

The new cable tie installation tool can fasten and cut nylon cable ties quickly & safely

Read More

.jpg?v=7ec45b5f)