Cable Tie Installation Guidelines

Proper cable management not only enhances the aesthetic of a setup but also prevents potential hazards. Therefore, please take some time to install cable ties to enjoy a tidier and more efficient environment. Here are some key points on how to safely install cable ties, which will keep cables organized and untangled, allowing the ties to function effectively.

| 1. | First, choose an appropriate cable tie, ensuring it is long enough to wrap around the cables or objects to be bundled. Pay attention to the weight and spacing of the cables and objects to ensure suitability. |

| 2. | Next, wrap the zip tie around the bundled cables or objects, forming a loop and inserting the tip into the slot. When installing the cable tie, maintain a smooth and stable action, applying force gently and slowly in a straight line to ensure a good installation. |

| 3. | Be mindful not to pull the cable tie with excessive force, avoid using rapid threading methods, do not pull the cable tie in all directions, and do not manually tighten the cable tie to 100% causing overtightening. To ensure the teeth and structure of the cable tie do not fail due to excessive wear during installation. Additionally, remember to avoid wrapping too tightly as it may damage the cables or bound objects; ensure there is enough slack for flexibility and future adjustments. |

| 4. | The optimal tightening force is half of the cable tie's claimed loop tensile strength. For instance, when using a standard 2.5mm width cable tie with a claimed loop tensile strength of 80N, it is recommended to use half that tightening force, 40N, for installation (80N÷2=40N); when using a standard 4.8mm width cable tie with a claimed loop tensile strength of 222N, it is recommended to use half that tightening force, 111N, for installation (222N÷2=111N). Therefore, it is recommended to use tensioning tools or cutting tools designed for cable ties. Using tools can ensure the magnitude, speed, and direction of the applied force, as well as the space retained after tightening. |

| 5. | When using a tensioning tool, adjust the rear tension control knob to set the appropriate tightening force, and trim off any excess tail, ensuring the cut end is smooth to avoid leaving sharp edges. |

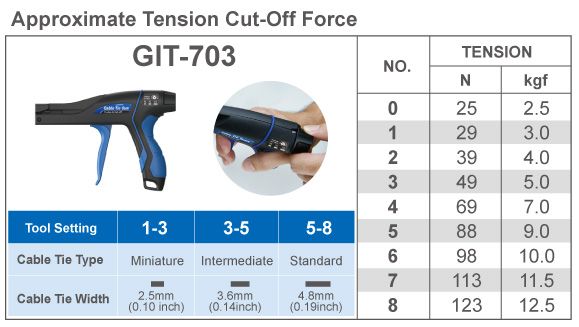

| 6. | The tensioning force of the cable tie tool, for example, setting the dial to "5", "6", "7", corresponds to forces of 88N, 98N, 113N, respectively. Such tensioning forces are suitable for tightening ST standard cable ties. Here is a table correlating the knob settings to the cutting forces, please refer to the information below.  |

| 7. | Finally, for more operating instructions for the tensioning tool, you can watch instructional video for more comprehensive information. |

By following these simple steps, you can safely install cable ties, ensuring their performance and stability, and achieving a neat and organized space.

For more information on cable ties or to determine which type of cable tie is best suited for your application, you can refer to our Cable Tie Selection Guide or consult with our professionals for guidance.

Featured product

Hot

Hot

Stainless Steel Ties

Hot

Hot

Stainless Steel Ties

With high resistance to various corrosive agents such as acids, alkali, UV, and rust, …

Read More Hot

Hot

Wire Ducts

Hot

Hot

Wire Ducts

The premium solution for routing and hiding wires in control panels.

Read More Hot

Hot

Standard Cable Ties

Hot

Hot

Standard Cable Ties

Available materials include heat stabilized, weather resistant and flame retardant polymers,...

Read More Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

The new cable tie installation tool can fasten and cut nylon cable ties quickly & safely

Read More

.jpg?v=7ec45b5f)