How to choose the right cable tie? What is their application for?

There are many types of cable ties, definitely not just the common and usual Nylon 6,6 cable ties.

Most cable ties are made of Nylon, invented by the American company Dupont in 1937. Nylon is one of the most widely used synthetic thermoplastics globally for its high strength, high dimensional stability, and high abrasion resistance.

During World War II 1939-1945, the invention of the aero-gas turbine engine accelerated the use of jet aircraft and the exponential growth in production. In order to repair these aircraft in a short time and to bundle the large number of lengthy wires of the aircraft, self-locking ties, similar to the hair curler concept, were used to fasten and bundle the cable wires, and to shorten the time to arrange the cables and to prevent hand calluses or injuries caused by the large number of tied wires during assembly.

In 1955, Kurt Robel filed a patent for nylon ties in France (FR1126581A), and in 1958, Maurus C Logan also published a patent document describing this concept (US3022557A).

In 1955, when the Vietnam War began, in addition to military aircraft, more and more civilian airliners were added to the fleet, as well as portable instant airbases, and aircraft were pre-wired to meet the demand for quick and immediate assembly on site. In addition to aircraft during the Cold War, space races, the manufacture of missiles, satellites and spacecraft, and even computers, used more complex and extensive wiring, and the installation and management of cables became more important and widespread.

The most common material is Nylon 6,6 cable ties, they are like an all-around product. They are available in different lengths, widths, tensile strengths, mechanical designs, colors, etc. Binding wires and cables together with cable ties in life can keep them in order and prevent damage to the wires or pipes, which could lead to the risk of fires in the wires.

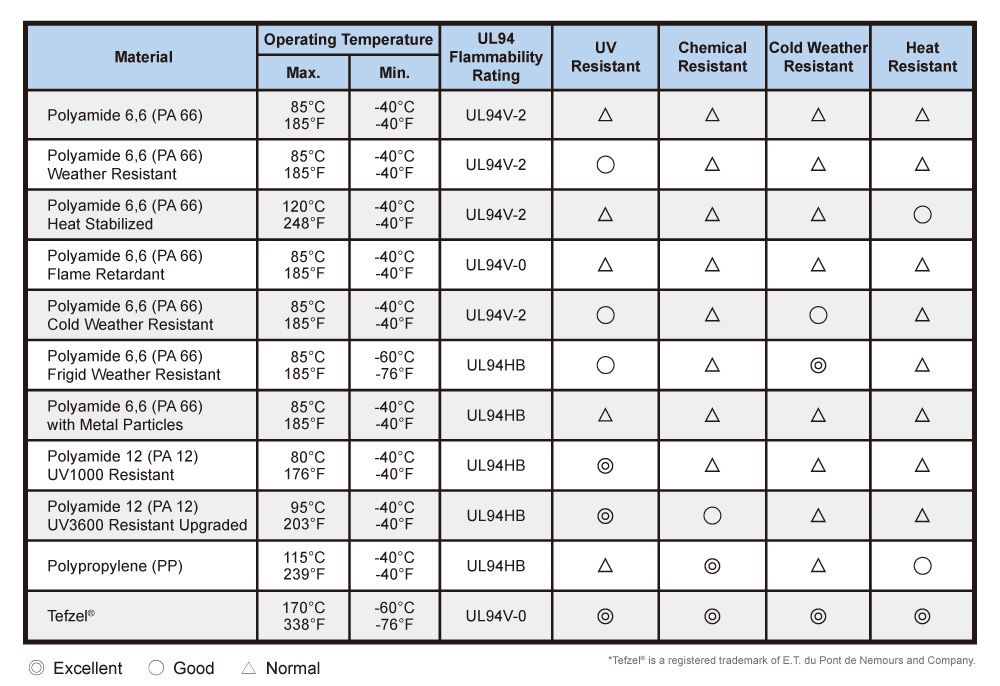

Different materials of ties have different characteristics and are used for different purposes in various industries. For example, in extreme cold climates, extreme harsh climates, extreme chemical environments, deserts and special industries, general Nylon 6,6 may not be able to adapt to temperature changes, chemical properties, etc., and may break or become fatigued in these special environments. Therefore, if you need a UV resistant solution, you can choose a Nylon 6,6 weather resistant material or a Nylon 12 material that will work better in outdoor environments, even in desert and solar field applications. In addition, cable ties with metal content are designed for the food and pharmaceutical industries to support quality assurance, such as HACCP, and metallic pigments can be detected by standard equipment, helping to reduce the risk of contamination. For visual detection, these cable ties are usually in blue.

The material determines which solution is right for your industry, from the most general Nylon, to additive materials such as heat-resistant, UV-resistant, cold-resistant, metal-detectable, Nylon 6, Nylon 12, or Polypropylene (PP), Polyethylene (PE), Ethylene tetrafluoroethylene (ETFE), stainless steel 304, stainless steel 316, etc.

The table below allows you to find out the characteristics of different materials according to your industry or application, and can help you select the right material, as well as provide a product overview for the professional and high-quality products offered by Hua Wei.

Material Type | Features | Application | Available products |

Standard Nylon 6,6 Material |

| Ideal for industrial, professional, air-handling space (exchange of environmental air) and indoor use | |

Flame Resistant / Self Extinguishing Material |

| Ideal for higher fire protection, areas where low smoke emission or low flammability are required, crowded and public areas | Flame Retardant Cable Ties |

Weather Resistant / UV Stabilized |

| Ideal for outdoor, solar, transportation, and air-handling applications | Weather Resistant Cable Ties |

Heat Stabilized / Resistant |

| Ideal for electrical, transportation, automotive, equipment application or where heat is generated | Heat Stabilized Cable Ties |

UV-Radiation 3600 Hours Resistant |

| Ideal for solar PV, dessert, and outdoor application | |

Extreme Environmental Stresses Resistant |

| Ideal for use in nuclear power facilities, chemical processing plants, semiconductor, defense, and medical industries | Tefzel Cable Ties |

Chemical Resistant / Aggressive Acids and Bases Substances Resistant |

| Ideal for chemical industry | Polypropylene Cable Ties |

Frigid Weather Stabilized (-60°C) |

| Ideal for frigid area applications, aviation, shipbuilding, refrigeration, and frozen food industries | Frigid Weather Resistant Cable Ties |

Cold Weather Stabilized (-40°C) Material |

| Ideal for frozen storage equipment, low temperature logistics distribution | |

Metal Detectable / Food Graded Material |

| Ideal for packaging and machine maintenance and management in the food and pharmaceutical and other contaminant sensitive industries | |

Stainless Steel Material |

| Ideal for applications in marine, oil and gas, mining, construction, chemical, maintenance, automotive and underground | |

Air Handling / HVAC Material |

| Used in heating or air handling spaces above drop ceilings and below raised flooring, and plumbing applications | HVAC Dust Cable Ties |

Colored Material |

| Ideal for decorating on autos, bicycles, plants, in enclosures and cabinets or for festive decorations |

Please contact us for more information. |

Download Catalog

For more information, Please Contact Us.

Featured product

Hot

Hot

Stainless Steel Ties

Hot

Hot

Stainless Steel Ties

With high resistance to various corrosive agents such as acids, alkali, UV, and rust, …

Read More Hot

Hot

Wire Ducts

Hot

Hot

Wire Ducts

The premium solution for routing and hiding wires in control panels.

Read More Hot

Hot

Standard Cable Ties

Hot

Hot

Standard Cable Ties

Available materials include heat stabilized, weather resistant and flame retardant polymers,...

Read More Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

The new cable tie installation tool can fasten and cut nylon cable ties quickly & safely

Read More

.jpg?v=7ec45b5f)