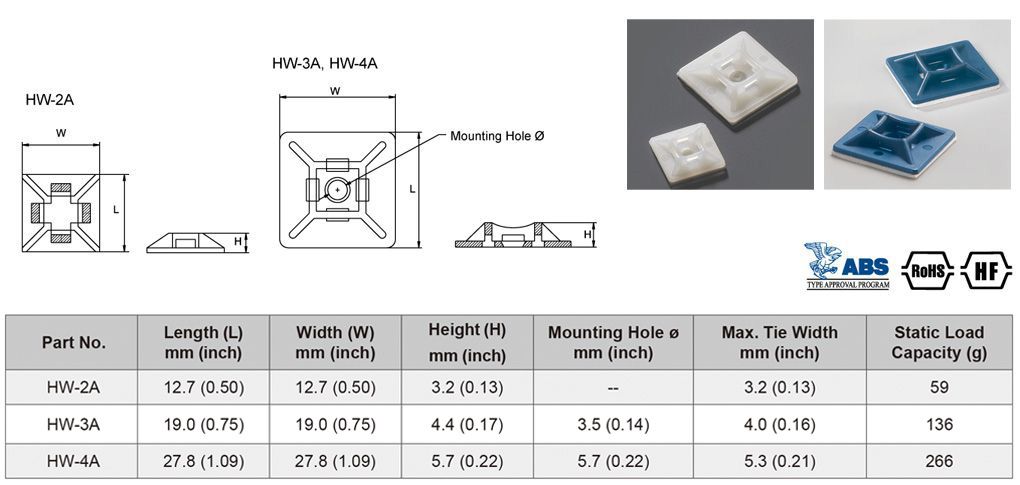

The Usage and Installation of Cable Tie Mounts

It is important to use the Cable Tie Mount to secure the cable and prevent the cable from shaking and bouncing all over the place. Due to frequent friction, cable may loosen or damage easily, which may affect the performance of the expensive module and electronic system.

Adhesive back fixed function are designed for pasting on a wide range of surfaces, including plastics, woods, cement walls, and metals. This back sticker will hold it in place. Moreover, for strengthen the stability, drilling the screw is also a choice.

Hua Wei has developed several zip ties mounts materials and can be applied in different industries. These materials including the basic nylon 66, metal detectable plastic specially designed for food industry, and nylon 12 for solar energy industry and so on.

Features

- Available in either “Screw Mount” or “Self-Adhesive Mounting”

- Simple to install with a screw or bolt, the ties mount give excellent security, particularly in areas of high vibration.

- Designed to offer the maximum surface area, and in conjunction with the specially developed adhesive ensures that a very high pull-off force is achieved

- The tie mounts offer a 4-way entry for the cable tie enabling quicker and more flexible installation

- Designed specifically for holding heavier cable bundles

The following video shows the installation and effect of the zip tie mounts:

Cable Tie Mounts Installation Guide

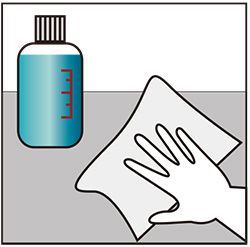

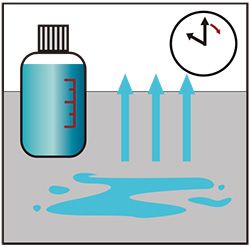

1. Surface PreparationTo ensure optimal adhesion, please follow these steps:

|

|

|

|

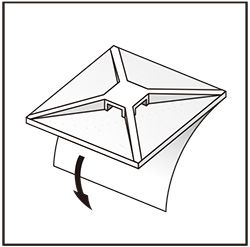

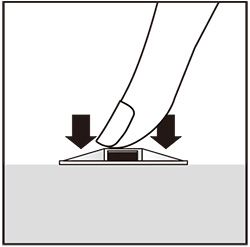

2. Install the Cable Tie Mounts

|

|

|

|

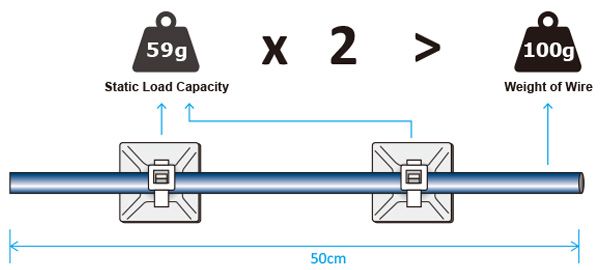

3. Cable Tie Mount Load Capacity

To ensure that the cable tie mount can safely and securely support the equipment, calculate the required number of mounts based on the following formula:

|

100/59=1.69 rounded to 2 Conclusion: This 50cm wire needs two HW-2As to carry it  During the installation process, ensure that each mount's load capacity can withstand the equipment's weight. If the equipment has a larger or uneven center of gravity, increase the number of mounts to distribute the load, thus improving safety. |

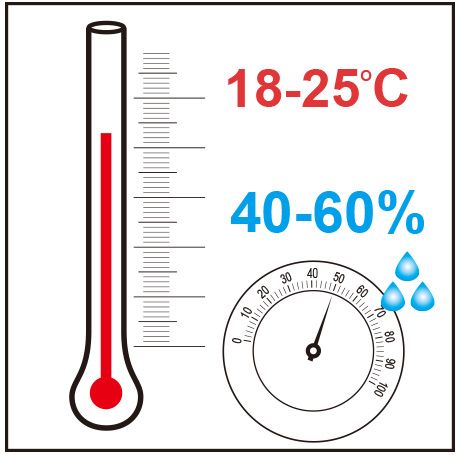

4. Storage Conditions

|

|

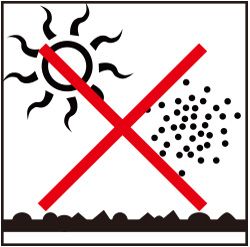

Other Precautions:

|

|

To see more cable tie mount series, please click here.

If you need our professional person to contact you, please click here.

Featured product

Hot

Hot

Stainless Steel Ties

Hot

Hot

Stainless Steel Ties

With high resistance to various corrosive agents such as acids, alkali, UV, and rust, …

Read More Hot

Hot

Wire Ducts

Hot

Hot

Wire Ducts

The premium solution for routing and hiding wires in control panels.

Read More Hot

Hot

Standard Cable Ties

Hot

Hot

Standard Cable Ties

Available materials include heat stabilized, weather resistant and flame retardant polymers,...

Read More Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

The new cable tie installation tool can fasten and cut nylon cable ties quickly & safely

Read More

.jpg?v=7ec45b5f)