Plastic Cable Tie

Plastic cable tie (also known as a zip tie, hose tie or zap strap) is a type of fastener, for fastening, bundling, clamping and identifying in a variety of applications throughout the physical infrastructure, primarily electric cables or wires.

Cable ties in a wide range for nearly every application situation, for example: electrical installation, construction industry, Automotive industry, packaging industry or under extreme environmental conditions like in the offshore industry...etc.

Generally speaking, there are different types of plastic zip ties, including the following categories.

- Standard Cable Ties: PA66, PA66 weather resistant (UV), PA66 heat stabilized, PA66 flame-retardant (UL94V-0), round head, Tefzel cable tie, frigid weather resistant, cold weather resistant, polypropylene (PP) cable tie …etc.

- Releasable Cable Ties: easy release and re-use, beaded type, PE, polyamide, hook and loop…etc.

- Mountable Cable Ties: Screw mount, push mount, fir-tree mount, chassis mount…etc.

- Outside Serrated: standard and low profile cable ties are available.

- Identification: marker ties and security seals are available.

- Special Purpose: solar cable ties, metal detectable cable ties, tuckaway cable ties, double loop cable ties, stopper ties, air conditioner tube ties…etc.

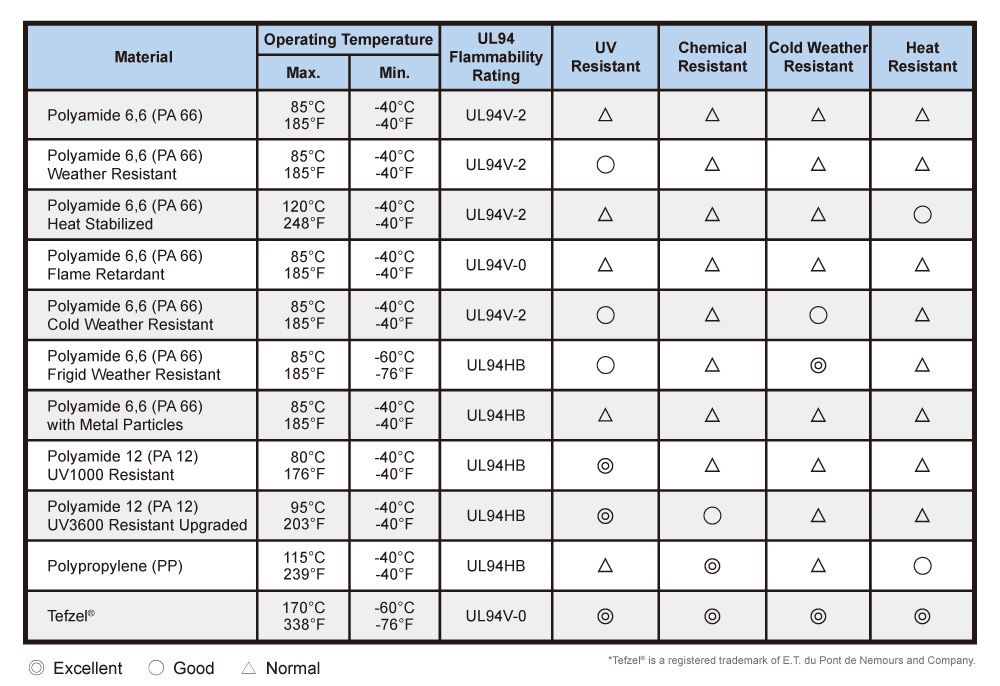

- Polyamide 6,6 standard for temperature conditions of up to +85˚C (185˚F).

- Polyamide 6,6 Weather Resistant for outdoor use.

- Polyamide 6,6 Heat Stabilized for temperature conditions of up to +120˚C (248˚F).

- Polyamide 6,6 Flame Retardant UL94V-0 for high standards of fire protection.

- Polyamide 6,6 Cold Weather Resistant can be exposed to zero temperatures for a long time.

- Polyamide 6,6 Frigid Weather Resistant enhanced flexibility and toughness for -60˚C (-76˚F) cold temperature applications.

- Polyamide 6,6 Metal Detectable can be detected by a metal detector.

- Polyamide 12 with high UV resistance, suitable for long-term outdoor use.

- Polypropylene (PP) are higher chemical resistant for use in chemical process industry or related hash environments.

- Tefzel / ETFE are recommended for applications requiring high resistance to environmental stresses such as chemical attack, gamma radiation, ultraviolet radiation, and extreme temperatures.

- Over 45 years experiences in designing and manufacturing of cable ties.

- Core technology: Precise stamping and molding injection.

- Rich experience and specialty of precise molding in engineering plastic Polyamide 6,6

- Advanced molding facilities and outstanding R&D teamwork

- Our in-house molding capability allows great flexibility in production and enables us to develop products collaboration with our clients.

- Providing customize packaging design and work in process with your brand.

- Stable supply chain with on-time delivery.

Cable Ties Standard

|

|

|

|

PA66 Cable Tie 18 to 250 pound tensile strengths, UL Plenum Rated |

PA66 Weather Resistant (UV) UV resistant, for outdoor and indoor use |

PA66 Heat Stabilized heat stabilized up to 120°C (248°F) |

|

| |

|

PA66 Flame-Retardant (UL94V-0) for low smoke density and fire resistance Rated |

Round Head Cable Ties unique design with round, smooth edges | |

|

|

|

|

Tefzel ® Cable Tie for extraordinary chemical & gamma radiation resistance |

Ethylene Tetrafluoroethylene (ETFE) Cable Tie chemical resistant, ideal for chemical industry |

Polypropylene Cable Tie low density, chemical resistance, food grade material |

|

| |

|

Frigid Weather Resistant Cable Ties for -60°C cold temperature and frigid area applications |

Cold Weather Resistant Cable Ties for -40°C cold temperature applications |

Special Purpose Cable Ties

_Cable_Ties.jpg) |

|

|

|

Solar (PA12) Cable Tie for long-lasting UV resistant and solar industry |

Metal Detectable Cable Ties for contaminant sensitivity and food safety industry, FDA |

Tuckaway Cable Ties for heavy duty applications |

|

|

|

|

Double Loop (Head) Cable Ties for securing two bundles or attach cords |

Stopper Ties for preventing bundling from being too tight |

Air Conditioner Tube Ties for fixing air conditioner tubes or pipes |

|

|

|

|

Décor (Metal Color Plating) Ties for attractive finishes on autos, bicycles…etc. |

Carbon Fiber Printing Cable Ties for attractive finishes on autos, bicycles…etc. |

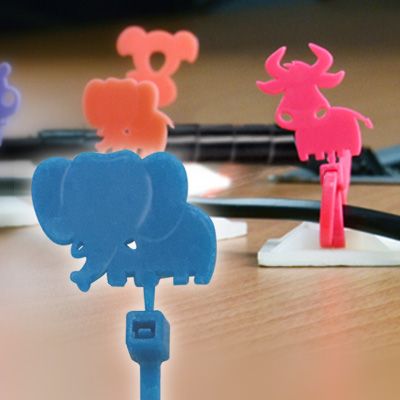

Special Shaped Cable Ties various special shapes for decorating |

Releasable Cable Ties

.jpg) |

.jpg) |

|

|

Releasable Cable Ties (GTR) for reuse and easy removal |

Releasable Cable Ties (GTRN) for reuse and easy removal |

Beaded Cable Ties easy to open and adjust, ideal for Home / Office wire and cord management. |

|

|

|

|

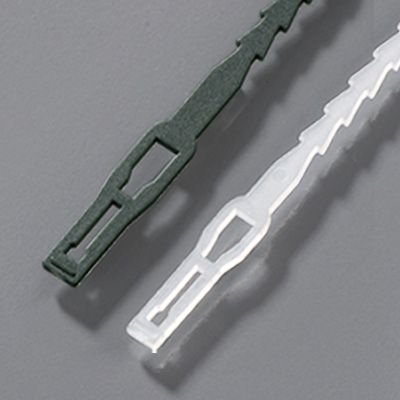

Gardening Cable Ties for easy bundling and holding items together, application in garden |

Contour Cable Ties for bundling and holding items together, primarily electrical cables or wires |

Hook and Loop Cable Ties to maintains network data integrity by protecting against over-tensioning of copper and fiber cables |

| ||

|

Hook and Loop Roll Strips to maintains network data integrity by protecting against over-tensioning of copper and fiber cables |

Mountable Cable ties

|

|

|

|

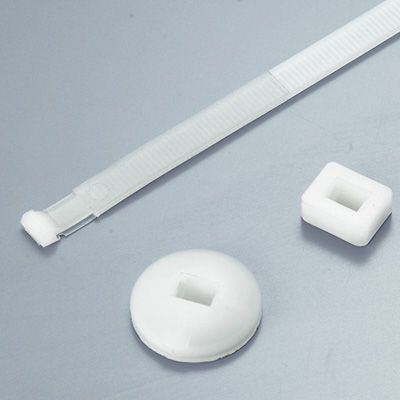

Screw Mount Cable Ties for fastening with an existing hole and fixing at the boards |

Push Mount Cable Ties for fastening with an existing hole and fixing at the board application |

Chassis Cable Ties for a single hole and are widely used in the automotive, truck and heavy equipment |

|

| |

|

Fir-Tree Mount Cable Ties Cable ties with mountable head are not only for bundling and holding items together, but also for fixing at the boards. |

Cable Ties and Fir-Tree Mount Assemblies Cable ties with mountable head are not only for bundling and holding items together, but also for fixing at the boards. |

Outside Serrated Cable ties

|

|

.jpg) |

|

Outside Serrated Cable Ties to reduce abrasion on sensitive wires, cables and hoses |

PA66 Low Profile Cable Ties smooth, low-profile head that helps prevent snagging |

PA12 UV1000 Low Profile Cable Ties smooth, low-profile head that helps prevent snagging |

Identification Cable ties

|

| |

|

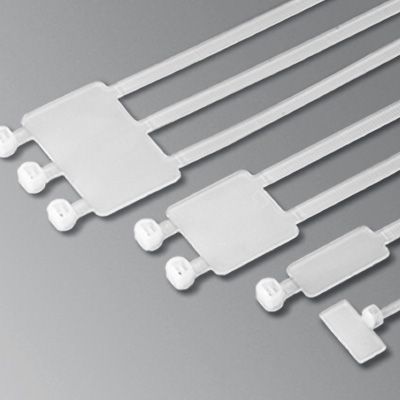

Identification Cable Ties for simple identification and securing of cable bundles in one step |

Security Seals unique identification meet the security regulation of customhouse and logistic industry |

Download Catalogue

Need quotation? Please contact us.

Product Certification

Hua Wei’s cable ties have gained UL, CE, UKCA, ABS, DNV GL, BV, and Lloyd's Register accreditations and are all compliant with RoHS and REACH regulations.

To know more information? Please contact us.

Material Description

Plastic ties can be made from a variety of materials depending on the application. Polyamide, also known as nylon, is an ideal material that can be processed by injection molding into high quality products. Approximately 90% of Hua Wei's ties and fasteners are made from this material. For higher chemical resistance or certain industries, we can use other materials to suit the application.

RECOMMENDED TOOLS

|  |  |

GIT-703

GIT-704G

GIT-709

OPTIMUM STORAGE CONDITIONS

Optimum storage conditions for cable ties made of polyamide (PA)

|

|

| Always store ties in the sealed plastic bag made of polyethylene. Once opened you should use the ties as quick as possible. | Do not store the product in sunlight; for example, on the windowsill. |

|

|

| Store the product away from direct sources of heat. Avoid contact with heat: for example, do not place on the radiators. | The ideal storage conditions are those of the central European standard climate: 23°C(73.4°F), 50% relative humidity. |

Why Choose Hua Wei?

Remarks: Hua Wei is a professional OEM factory, followed the MOQ for each order.

Need Quotation? Please Contact Us.

Featured product

Hot

Hot

Stainless Steel Ties

Hot

Hot

Stainless Steel Ties

With high resistance to various corrosive agents such as acids, alkali, UV, and rust, …

Read More Hot

Hot

Wire Ducts

Hot

Hot

Wire Ducts

The premium solution for routing and hiding wires in control panels.

Read More Hot

Hot

Standard Cable Ties

Hot

Hot

Standard Cable Ties

Available materials include heat stabilized, weather resistant and flame retardant polymers,...

Read More Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

The new cable tie installation tool can fasten and cut nylon cable ties quickly & safely

Read More

.jpg?v=7ec45b5f)