Technical information

Optimum Storage Conditions for PA 6,6 Cable Ties

Hua Wei cable ties, fastenings and fixings are manufactured from high-quality polyamide (PA). This industrial synthetic material is mainly processed using injection moulding, but can also be extruded.Polyamide is a hygroscopic material. This material generally shows higher water absorption than other engineering plastics. This leads to dimensional changes to finished parts, a reduction in strength, and also to changes in electrical insulating characteristics. The degree of moisture absorption depends on the type of plastic and the ambient conditions such as temperature, humidity and contact time.Besides, the differentiation of the width and thickness of cable tie the moisture content will be different. In our product line, the moisture content of cable tie that we recommend circumscription is around 2.5% approximately.The packaging used by Hua Wei ensures that the water content in the material remains constant. Therefore, it is important to store the products in their original packaging to preserve the quality of the ties.

Cable Tie Installation Guidelines

Proper cable management not only enhances the aesthetic of a setup but also prevents potential hazards. Therefore, please take some time to install cable ties to enjoy a tidier and more efficient environment. Here are some key points on how to safely install cable ties, which will keep cables organized and untangled, allowing the ties to function effectively.

The Key Role of Cable Ties in Industry: Flame Retardancy and Corrosion Resistance

Cable ties play a crucial role in modern industry and daily life, especially in securing and bundling cables, pipes, and other facilities. Different materials of cable ties possess unique characteristics, particularly in terms of flame retardancy and corrosion resistance, which directly impact their application safety and durability.Firstly, flame retardancy is essential for many applications of cable ties, especially in securing electrical equipment, cable bundles, and other scenarios requiring fire safety protection. The PA66 cable ties we use comply with the UL94V-2 standard, indicating excellent performance in flame tests by preventing flame spread and reducing the risk of fire, thereby safeguarding surrounding environments and equipment.

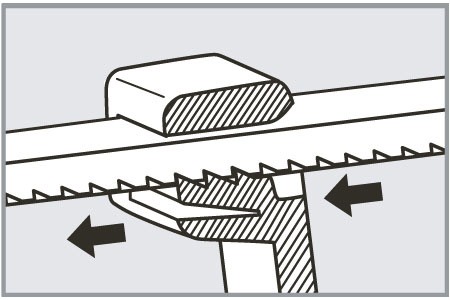

The Locking Mechanism of Cable Ties

With this technology, Hua Wai produces 90% of polyamide (PA) cable ties. In order to cover a variety of applications, there is a large selection of products, for example: releasable versions and outside-serrated versions.The pawl integrates with the strap as one-piece cable tie, thereby building in inherent strengths.

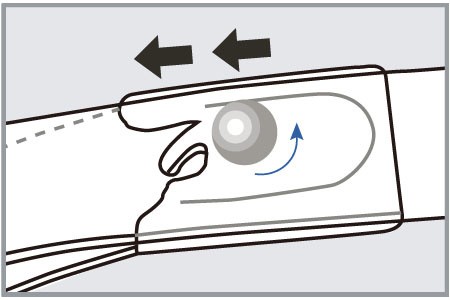

The Locking Mechanism of Ball Lock Type Stainless Steel Cable Ties

Stainless steel cable tie is formed with stainless steel grades 304 or 316.The MLG range of cable ties has no serrations on the strap, and the strap parallels through the head, gliding under a metal ball-bearing locking mechanism. By using the GIT-705 application tool the cable tie is tensioned and the strap cut to a flush finish.

Determination of Minimum Tensile Strength

The minimum tensile strength is a critical selection criterion for cable ties. It expresses how much loading a cable tie can bear. This minimum tensile strength is determined in accordance with the Military Specification and Standards of the USA. The test procedure/conditions as below is according to UL/IEC 62275:

How to choose the right cable tie? What is their application for?

There are many types of cable ties, definitely not just the common and usual Nylon 6,6 cable ties.Most cable ties are made of Nylon, invented by the American company Dupont in 1937. Nylon is one of the most widely used synthetic thermoplastics globally for its high strength, high dimensional stability, and high abrasion resistance.During World War II 1939-1945, the invention of the aero-gas turbine engine accelerated the use of jet aircraft and the exponential growth in production. In order to repair these aircraft in a short time and to bundle the large number of lengthy wires of the aircraft, self-locking ties, similar to the hair curler concept, were used to fasten and bundle the cable wires, and to shorten the time to arrange the cables and to prevent hand calluses or injuries caused by the large number of tied wires during assembly.In 1955, Kurt Robel filed a patent for nylon ties in France (FR1126581A), and in 1958, Maurus C Logan also published a patent document describing this concept (US3022557A). In 1955, when the Vietnam War began, in addition to military aircraft, more and more civilian airliners were added to the fleet, as well as portable instant airbases, and aircraft were pre-wired to meet the demand for quick and immediate assembly on site. In addition to aircraft during the Cold War, space races, the manufacture of missiles, satellites and spacecraft, and even computers, used more complex and extensive wiring, and the installation and management of cables became more important and widespread.The most common material is Nylon 6,6 cable ties, they are like an all-around product. They are available in different lengths, widths, tensile strengths, mechanical designs, colors, etc. Binding wires and cables together with cable ties in life can keep them in order and prevent damage to the wires or pipes, which could lead to the risk of fires in the wires.Different materials of ties have different characteristics and are used for different purposes in various industries. For example, in extreme cold climates, extreme harsh climates, extreme chemical environments, deserts and special industries, general Nylon 6,6 may not be able to adapt to temperature changes, chemical properties, etc., and may break or become fatigued in these special environments. Therefore, if you need a UV resistant solution, you can choose a Nylon 6,6 weather resistant material or a Nylon 12 material that will work better in outdoor environments, even in desert and solar field applications. In addition, cable ties with metal content are designed for the food and pharmaceutical industries to support quality assurance, such as HACCP, and metallic pigments can be detected by standard equipment, helping to reduce the risk of contamination. For visual detection, these cable ties are usually in blue.The material determines which solution is right for your industry, from the most general Nylon, to additive materials such as heat-resistant, UV-resistant, cold-resistant, metal-detectable, Nylon 6, Nylon 12, or Polypropylene (PP), Polyethylene (PE), Ethylene tetrafluoroethylene (ETFE), stainless steel 304, stainless steel 316, etc.The table below allows you to find out the characteristics of different materials according to your industry or application, and can help you select the right material, as well as provide a product overview for the professional and high-quality products offered by Hua Wei.

The Usage and Installation of Cable Tie Mounts

It is important to use the Cable Tie Mount to secure the cable and prevent the cable from shaking and bouncing all over the place. Due to frequent friction, cable may loosen or damage easily, which may affect the performance of the expensive module and electronic system.Adhesive back fixed function are designed for pasting on a wide range of surfaces, including plastics, woods, cement walls, and metals. This back sticker will hold it in place. Moreover, for strengthen the stability, drilling the screw is also a choice.Hua Wei has developed several zip ties mounts materials and can be applied in different industries. These materials including the basic nylon 66, metal detectable plastic specially designed for food industry, and nylon 12 for solar energy industry and so on.

Guide to Choosing the Suitable Cable Tie Holders & Mountings

What are Cable Tie holders & Mountings? Industries and Applications

Cable tie holders can be used in a variety of different industries, from HAVC, electronic circuits, building, solar work to automotive and different industries with applications such as HVAC components, panel, white goods, junction boxes, rack enclosure cabinets and electric cable enclosures. Many data cabinet back panels have pre-drilled or pre-punched holes for accepting screw fastened cable tie mounts and other accessories. Therefore, it is important to use the right mountings in different places. One indicator of the successful point of a large and professionally assembled project is the cables and conductors to be discreetly installed by professional design.

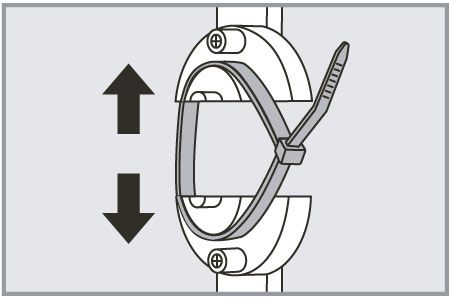

What Are P-Style Cable Clamps and How to Use Them?

What are P Clamps?

P clamps also known as P-Style or R- Type are designed to assist in bundling and clamping applications for pipes, hoses and wires. Available in various materials and sizes, these screw mount clamps are stocked in a choice of different mounting hole and screw sizes dependent on your application and requirements. Besides keeping things organized they can also prevent your wiring installation from becoming a trip hazard by keeping loose wires out of the way. They work by way of securing different types of cable to a surface or join. This could be a wall, skirting board or a ceiling.

How to Properly Install Lighting Fixtures and Replace Wiring

Installing a light fixture at home can seem daunting, especially if you’re new to wiring. Since wiring involves electricity, which can be dangerous, it's important to approach the task with care. By taking basic precautions and understanding the fundamentals of circuits and the wiring involved, you can make the process safer and more manageable. With products from Hua Wei Industrial, wiring and installing new light fixtures becomes not only easier but also safer, allowing you to complete your project with confidence.

Wiring and Installation Guide for Junction Boxes

When inspecting your home's electrical system, you'll find various components, including cables, outlets, switches, circuit breakers, and an essential box known as the junction box. According to the National Electrical Code (NEC) and local building regulations, the installation of junction boxes is mandatory to ensure the safety and compliance of the electrical system. Reading our Wiring and Installation Guide for Junction Boxes for more expert advice.

The King of Plastic, Tefzel Is the Best to Make the Perfect Product

Tefzel® ETFE (ethylene-tetrafluoroethylene) resins are melt-processable copolymers with excellent physical toughness, radiation resistance, chemical resistance, UV resistance, and resistance to extreme temperature changes. Tefzel® is FDA Compliant and the name applied by DuPont™. This wide variety of fabrication possibilities combines with the following important properties to offer a unique balance of capabilities.

Introduction to Detectable Materials, Products, and Inspection Approaches

Why do we need metal detectable materials?

In the food production and packaging industry, the primary goal is to manufacture and deliver high-quality, healthy, and safe products for consumers. To achieve this goal requires the implementation of strict quality control methods to prevent food contamination. One of the most common sources of food contamination are from broken or worn equipment component; especially during production and packaging operations.

What is the Application for Metal Detectable Material?

Why cable ties need to pass FDA Testing? What are the Benefits to Food Safety?

In the process of food production, there are various hazards that can lead to errors in sanitation management, including microorganisms and foreign substances entering the food processing process. In the late 1980s, the first batch of detectable products were used in food production, which was characterized by embedding or sticking iron filings into items with high risk of contamination, so that if they were mistakenly entered, they would trigger a metal detector at the end of the production line.

Introduction the characteristics and application of Nylon 12 (Polyamide 12 / PA 12) material

Nylon 12 Material Introduction and Characteristics

Nylon 12 is a nylon polymer. It is made from ω-amino lauric acid or laurolactam monomers that each have 12 carbons, hence the name “Nylon 12”. Its characteristics are between short-chain aliphatic nylons (such as PA 6 and PA 66) and polyolefins. PA 12 is a long carbon chain nylon. Low water absorption and density, 1.01 g/mL, result from its relatively long hydrocarbon chain length, which also confers it dimensional stability and an almost paraffin-like structure. The Nylon 12 properties include the lowest water absorption characteristics of all polyamides, which means any parts made from PA 12 should remain stable in humid environments.

How to Verify the Weather Resistance of Plastics?

Xenon Arc Accelerated Weathering Test Methods for Solar Cable Ties

To verify the weather resistance of plastics, methods such as natural exposure and artificial accelerated tests are mainly adopted. However, since natural exposure is direct exposure in the natural environment, this method is extremely time-consuming, and is affected by environmental factors, and has low reproducibility. Therefore, the weather resistance of materials is mainly based on artificial aging tests, and the most common method is light aging test.

New Product

Featured product

Hot

Hot

Stainless Steel Ties

Hot

Hot

Stainless Steel Ties

With high resistance to various corrosive agents such as acids, alkali, UV, and rust, …

Read More Hot

Hot

Wire Ducts

Hot

Hot

Wire Ducts

The premium solution for routing and hiding wires in control panels.

Read More Hot

Hot

Standard Cable Ties

Hot

Hot

Standard Cable Ties

Available materials include heat stabilized, weather resistant and flame retardant polymers,...

Read More Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

Hot

Hot

(GIT-703) Cable Tie Tensioning Tool

The new cable tie installation tool can fasten and cut nylon cable ties quickly & safely

Read More